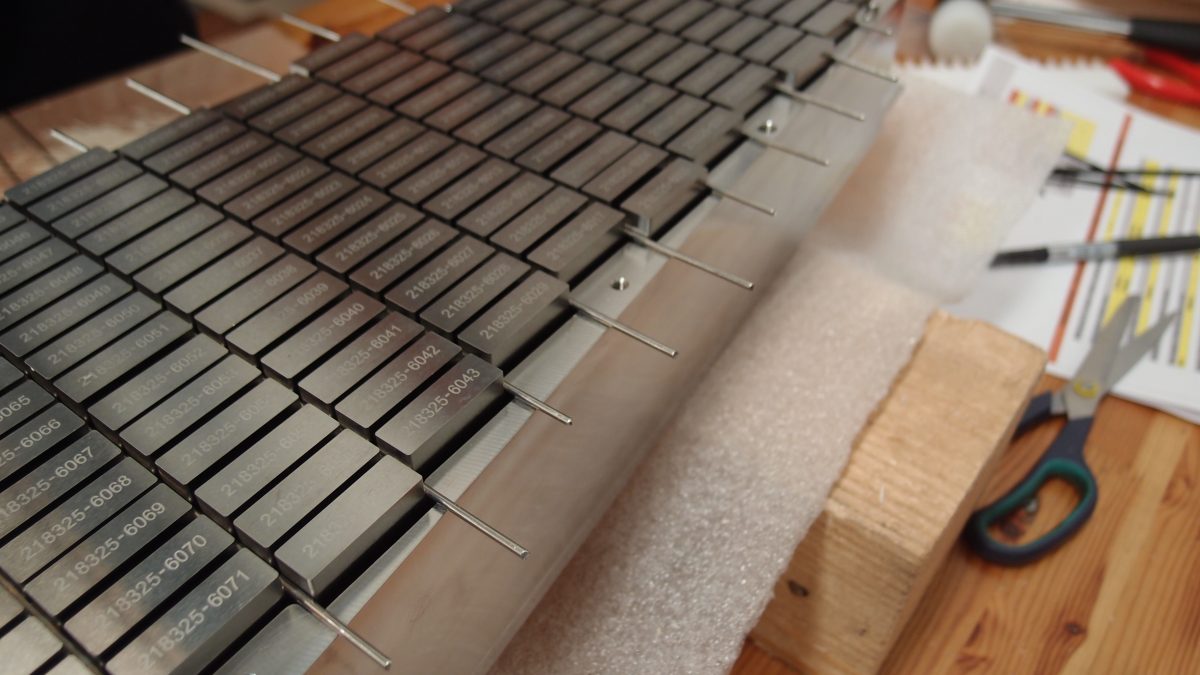

SUCCESSFUL CASSETTES ASSEMBLY NEW MILESTONE FOR ESS BILBAO

OLYMPUS DIGITAL CAMERA

ESS Bilbao manufacturing team has successfully completed the assembly of the 36 cassettes which contained the tungsten brick for the target wheel. The wheel has approximately 7,000 tungsten bricks cradled in the stainless steel cassettes cooling by helium and wrapped in a pressurised stainless-steel vessel. The helium is introduced by a coaxial pipe and circulates through several open volumes to guaranty and homogeneous inlet pressure in from of the cassette. Thus a precise machining process has been necessary since the beginning. In addition, the process has been manufactured under nuclear quality control standards.

Tungsten bricks are placed on the cassettes in the corresponding position and have to be fit to avoid any displacement of them. The upper cover are placed with the only help of the stainless steel positioners that originally came with the cassettes and stainless steel wires to hold the bricks in its position until the final assembly.