Vacuum

The Vacuum Lab has the capabilities to ensure the compatibility and correct operation of all the components that will work in a Ultra High Vacuum environment (<10-7 mbar).

CHARACTERISTICS

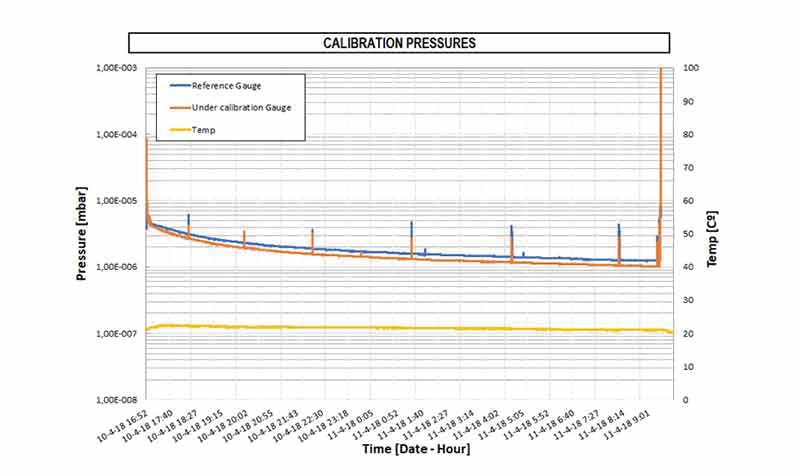

Vacuum gauge calibration by direct comparison with a reference Gauge

- The Calibration of the vacuum gauge is done by exposing both gauges (Reference and Under Calibration) to the same pressure (density and velocity distribution ) of calibration gas molecules.

- The calibration chamber is pumped down by a Diaphragm pump and Turbomolecular pump (Leybold TurboLab 80), the reference gauge is a combo of a Bayard Alpert hot cathode and a Pirani gauge (Leybold ITR90), the gas pressure inside can be varied by a the Dosing Valve (VAT 21124-KE0X).

- The calibration is made following the ISO 3567:2011 in the pressure range between 5*10-7 mbar to 5*10-5mbar.

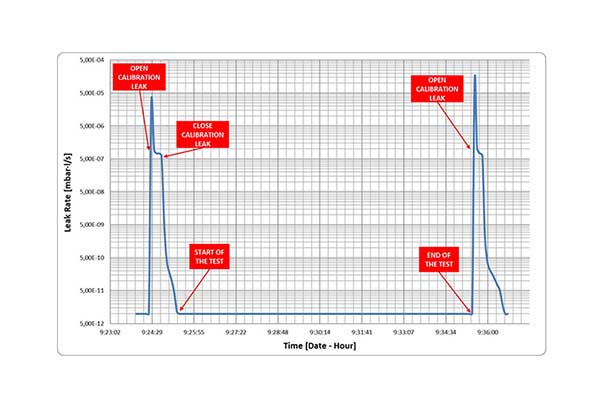

Leak detection testing

- The leak testing used is the Tracer Gas method – Total; according to the EN 1779 – A1.

In this test a pressure difference is created across the boundary of the object to be tested, this is obtained by evacuation of the object to be tested (vacuum vessel). Once the vessel is under vacuum the Tracer gas (helium) is applied to the external surface enclosing the object totally in a plastic bag. - The vacuum chamber is pumped down by a Primary and Turbomolecular pump (Pfeiffer ACP15 & HiPace700), once the required pressure is achieved the primary pump is isolated and is substituted by the Leak Detector (Leybold PhoeniX L 300) and Calibrated External Leak (INFICON TL7).

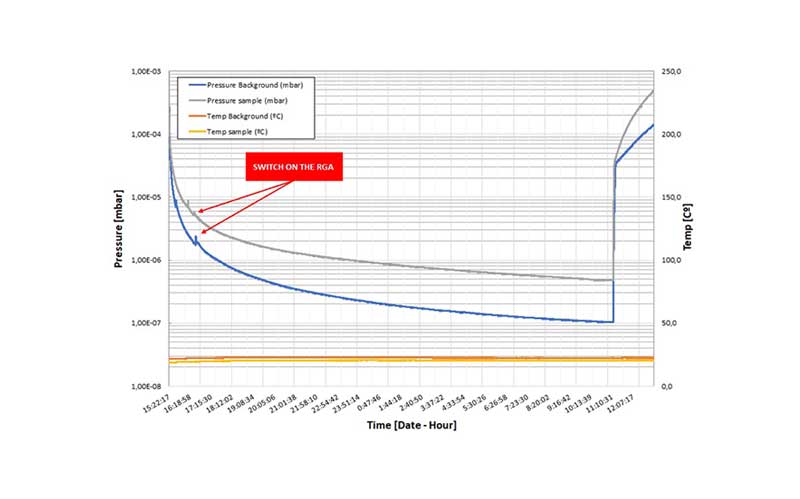

Outgassing Test

The outgassing Rate

- A measurement of the pressure increase of a sample inside a Test chamber is taken after 20 hours of pumping down and after is suddenly isolated from the pumps.

- The vacuum chamber is pumped down by a Primary and Turbomolecular pump (Pfeiffer ACP15 & HiPace700), the pressure is registered by a combo of a Bayard Alpert hot cathode and a Pirani gauge (Leybold ITR90) and the isolation is made by an all-metal angle valve (VAT 54132-GE02).

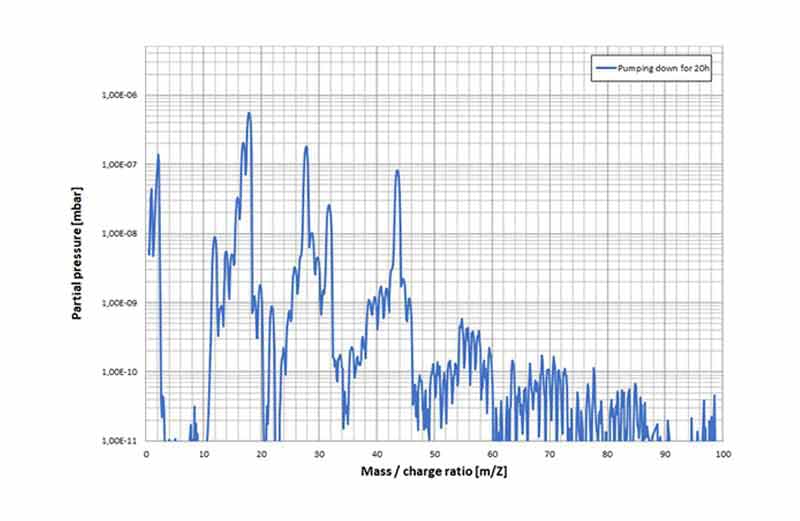

%HC Outgassing

- A measurement of the mass spectrum of the vacuum chamber is taken over the mass range of 1-100 uma. The measurement can be taken at any time and any pressure if the system is below the 5*10-6 mbar.

- The outgassing rate due to hydrocarbon (%HC) is to be calculated as follows:

- %HC = Sum of peaks above 40 uma/ sum of all peaks.

- The vacuum chamber is pumped down by a Primary and Turbomolecular pump (Pfeiffer ACP15 & HiPace700), the pressure is registered by a combo of a Bayard Alpert hot cathode and a Pirani gauge (Leybold ITR90) and the mass spectrum is taken by General Purpose Residual Gas Analyzer (MKS e-Vision 2).